Moreover, from comparisons of our internal calibrations with those of the World Radiation Center, PMOD or accredited labs, we have seen that Kipp & Zonen always has done a good job delivering accurate calibrations. It was an easy decision to go for it and start a period of intensive collaboration between R&D and the quality manager.

The customers that require accredited calibration are often in an industry that works according to standards and requires accredited equipment calibrations. We are happy that we can now supply this to our customers in the solar and car industry. We have limited the scope of the accreditation to the products that these customers mainly use: pyranometers and pyrheliometers.

What does ISO/IEC 17025 accreditation mean in practice

The core message of ISO/IEC 17025 is: prove that you are a competent calibration lab. In practice: work as described; describe how you work, and make sure you can prove this. There are no specific requirements for pyranometers, it is a generic standard.

We already had proper calibration procedures in place as well as quality checks, so that was nothing new. Proving that these quality checks are performed on a regular basis was not yet implemented. Now this is done, so at any moment we can prove that the calibration setup performs up to standard.

Preparations for ISO/IEC accreditation

The implementation of ISO/IEC 17025 is similar to ISO 9001. We made a handbook consisting of a management section on the calibration organisation and the staff, and a technical section where all specific details about pyranometer and pyrheliometer calibrations are covered. The latter section refers to implementation in our lab of ISO 9847 and ISO 9846 for the pyranometer calibration and to ISO 9059 for the pyrheliometer calibrations. The technical section is closely monitored by the calibration committee, consisting of several R&D colleagues and product managers. For each step or procedure we had to think: how can we prove that we work this way?

Our implementation and solution

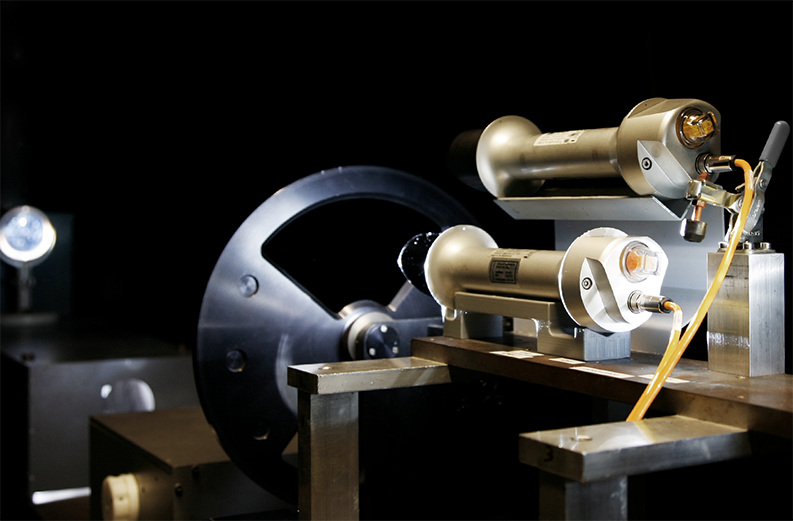

Years ago, Kipp & Zonen chose to automate the calibration processes, now we did an “upgrade” to meet ISO/IEC 17025. We have integrated the requirements of the standard in the software. For example daily tests are required before a regular calibration can be started, all measurement data is stored on the server and data-processing can be repeated afterwards, using original calibration measurement data. This level of automation also mitigated one of the largest risks: human influence or human errors. Since all steps done by the software are stored in the database, we can easily show proof that we work according to the described procedures.

With such an automated system many problems are solved, however, a very important requirement is that you prove that the software does “the right thing”. So an extended validation of automated process started. Many tests were performed and data was compared to old fashioned hand measured and manually calculated sensitivities.

We also have an official training program in place for the calibration staff, consisting of a course and test (both practical and theoretical). This course and test are yearly refreshed to ensure our staff is able to perform high quality calibrations at all times.

The audit by the accreditation council

Some weeks before the audit we had to send in all documentation; the management handbook, the calibration procedures, internal audit reports, the results of the proficiency tests, validation reports and uncertainty calculations. And we had to define the scope of the accreditation; the type of instruments and Calibration and Measurement Capability “CMC” value: how accurate and precise can we do these calibrations?

In return we received a list of points for improvement, after fixing these, we were ready for the actual site audit. The team leader and the technical expert visited our calibration lab. In two days following each single paragraph of the ISO/IEC 17025 standard the auditors checked how we had implemented it.

Fortunately, the outcome of the audit was great, only 6 shortcomings for a first ISO/IEC 17025 audit!

We had 6 weeks to solve the shortcomings: reference numbers on documents, last steps in improvement in data storage of software of automated calibration setup.

When this was done, the improved documentation and additional internal audit reports were sent to the accreditation council and got accepted. The auditors were pleased with the result and had indicated they would advise the accreditation council to vote “yes” for accreditation of Kipp& Zonen calibration laboratory. We had to wait 3 more weeks for the official monthly meeting of the Accreditation Council. And on 24th of October we received the good news: Kipp & Zonen is an accredited calibration lab for pyranometers and pyrheliometers!

I’m really proud that we have successfully finished this project and I thank the entire team for their strong commitment to reach our goal: an ISO/IEC 17025 accredited calibration laboratory!

If you would like to read more about ISO/IEC 17025 or the other international standards that apply in solar energy, download our whitepaper:

Blog by Joop Mes, Head of Calibration Committee at Kipp & Zonen