Location monitoring

Accurate solar monitoring starts with prospecting, or finding the optimal location. Because most countries have mountains, lakes or seashores, the microclimate can change across these areas. This means cloud formation often affects the solar radiation received. The decision to build a power plant at location A or B is based on local solar radiation conditions. The effect of clouds on solar radiation received, is not measured by satelites and can only be measured on the ground. Monitoring in advance will not only help choose the optimal location, it will also give a good estimate of available solar energy to calculate a project’s bankability.

Monitoring in operation

The next step is to monitor a power plant in operation. During this stage, efficiency, or performance ratio, is the most important factor. Independent of the technology used - PV, CPV or CSP - a thermopile radiometer will provide accurate and independent solar radiation data.

Both the pyranometer and pyrheliometer radiometers measure the irradiance in W/m2. When integrated over a day, the exact amount of available solar energy in Watt hours or Joules can be determined. Compared with the electrical output on that day this will give a power plant’s overall efficiency.

Other important information can be derived from data demonstrating a plant’s efficiency. Gradual changes in efficiency, for instance, may indicate solar panels or mirrors are soiled, which will mean cleaning actions should be scheduled. Sudden changes, however, may indicate a defective section, or a cable and connection problem. This would suggest further service actions should be taken to investigate the problem.

Other important information can be derived from data demonstrating a plant’s efficiency. Gradual changes in efficiency, for instance, may indicate solar panels or mirrors are soiled, which will mean cleaning actions should be scheduled. Sudden changes, however, may indicate a defective section, or a cable and connection problem. This would suggest further service actions should be taken to investigate the problem.

Different monitoring for different power systems

Only one accurate radiometer is required to monitor a solar power plant. But often two are used for redundancy. While one is used for calibration, the second will supply the required data for monitoring. The difference between monitoring photovoltaic (PV) and concentrated solar power (CSP), or concentrated PV systems (CPV), is not only about the different solar technology involved, but what part of solar radiation is used.

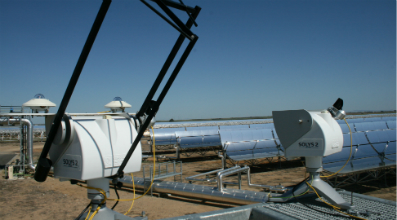

CSP and CPV plants mainly use direct solar radiation. This is because the direct beam of the sun is focused using mirrors (CSP) or lenses (CPV). Direct radiation can be measured with a pyrheliometer radiometer pointed at the sun. This radiation is called direct normal irradiance (DNI).

PV panels with fixed construction are positioned at an optimal tilt angle to catch the maximum amount of sun throughout the year. These flat panels not only use the direct part of solar radiation, but also global diffuse irradiance or GDI. In this case, a pyranometer is used which measures both direct and diffused radiation. This radiation is called global horizontal irradiance (GHI), when measured horizontally. For fixed PV panels an additional pyranometer is mounted and tilted so it is at the same angle as the panels. Global tilted irradiance (GTI) can then be measured. A single or dual-axis PV panel tracker can also be used to follow the path of the sun, making more efficient use of direct radiation.

Many meteorological stations measure global horizontal irradiance (GHI). When a station is nearby, less than 25km away, this data can be used for reference or for historical comparison of GHI at that location.

Many meteorological stations measure global horizontal irradiance (GHI). When a station is nearby, less than 25km away, this data can be used for reference or for historical comparison of GHI at that location.

The relationship between the global, direct and diffuse components of solar radiation is as follows: GHI = GDI + (cosØ x DNI). (Ø is the solar zenith angle.) Larger solar monitoring stations often measure all three components and cross-check using this formula to verify the individual components.

Smart monitoring

Thermopile radiometers generate an output signal from incoming solar radiation. While this means they do not need a power supply, consequently, the output signal is rather low. A typical radiometer gives about 25mV output on a sunny day. A sensitive data logger should be used to record these signals or an extra amplifier to increase the signal level. Recalibrating the radiometer will also require the amplifier or data logger settings to be changed.

In order to simplify this process, Kipp & Zonen developed pyranometers and pyrheliometers with a smart interface built in. This gives radiometers an amplified analogue output and a digital output, which makes it easier to interact with existing computer networks or PLCs (programmable logic controller). Since the introduction we have sold thousands of these smart sensors already, especially in the solar energy market.

This smart series of radiometers has the RS-485 standard for digital communication, with Modbus® protocol and temperature correction features across the range. The smart interface also provides faster response times and access to the radiometer model, serial number, as well as calibration data and history.

Comparing monitoring with satellites

In addition to local ground-based monitoring, satellite data is often available. This is a useful tool to get an idea of available solar radiation in a certain area. However, this data has around a 10 per cent uncertainty rate. To monitor the efficiency of a 100MW power plant, for example, the 10 per cent uncertainly rate would be equal to 10MW. Also, the time interval for satellite data can be one hour or more and the spatial resolution is usually only across 10 sq km.

In contrast, the best well-maintained pyranometers and pyrheliometers can provide solar radiation measurements with an uncertainty rate of 1 per cent or 2 per cent. This demonstrates the importance of using high-quality, precise instruments for accurate local measurements in solar monitoring.

Article by Ruud Ringoir, product manager at Kipp & Zonen for http://www.renewable-energy-technology.net/