Article by Dr. Jaya Singh, Director, BKC Weathersys Pvt. Ltd.

In this article, BKC WeatherSys explains how seemingly small deviations in solar radiation measurements have a major impact on estimates on performance ratios and plant efficiency.

Dr. Singh explains: “Although solar radiation measurement equipment presents a negligible fraction (less than 1-2%) of the total cost of a solar project, it is often the most neglected aspect of project development in India. In our experience of providing high accuracy solar weather monitoring stations across India, we find that the majority of solar power projects do not include obtaining accurate solar radiation ground measurements at the proposed location in the initial site assessment or planning stages. In fact, the most critical financial decisions are made on the basis of solar resource maps that are low resolution to begin with, and do not take into consideration local environmental and atmospheric conditions that have a significant impact on solar radiation and plant output, and consequently on the return on investment.

We estimate that over 65% of our solar weather monitoring stations are installed in the project development stage, and now increasingly after the plant is operational. Why this investment in accurate solar and weather monitoring equipment after the plant design and becoming operational?

It is only after the plant is functional that plant owners start evaluating performance and begin the process of predicting energy output. As the power output of PV solar panels are approximately proportional to the sun’s intensity, it is then that the lack of accurate solar parameters becomes evident. There is also a realization that it makes financial sense to validate solar resource databases upon which most plants are designed and investment decisions are being made, with accurate ground-based measurements during the lifecycle of the plant to reduce uncertainties in energy production.

In this more mature phase of the solar industry in India, we have started receiving requests for evaluating energy production by accurately measuring incoming solar radiation and validating it with satellite data and advanced solar forecasting models. As plant owners aim to predict their performance and energy output with overall uncertainties of 1 % - 2 % in solar radiation measurements, there is also an increased demand for the highest quality pyranometers and pyrheliometers. In fact, we routinely get requests for replacing existing solar weather monitoring instruments with high quality ISO certified, WRC (World Radiation Center) traceable instruments, such as those manufactured by Kipp & Zonen.

In this article, we describe one such case where an owner of a 5 MW plant contacted us six months after plant commissioning to evaluate whether the performance of the plant aligns with existing ground measurements and estimates made by their EPC contractor.

Once the plant was up and running, the plant’s performance and yield were continuously monitored, analysed, and compared with the expected values. The problem faced was that the energy output was higher than what could be expected based on performance ratios.

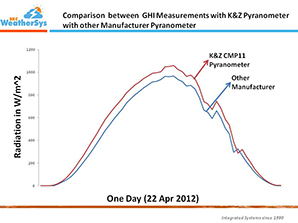

Our study included setting up three solar monitoring stations that included a Kipp & Zonen CMP 11 pyranometer at three different locations on the plant, and monitoring measurements for a period of over 1 month, and comparing these measurements with the plant's existing solar radiation monitoring equipment from another manufacturer. The CMP 11 (traceable to WRC, Davos, Switzerland) is an ISO-Secondary Standard pyranometer that allows for accurate measurement of GHI (Global Horizontal Irradiance).

Our study included setting up three solar monitoring stations that included a Kipp & Zonen CMP 11 pyranometer at three different locations on the plant, and monitoring measurements for a period of over 1 month, and comparing these measurements with the plant's existing solar radiation monitoring equipment from another manufacturer. The CMP 11 (traceable to WRC, Davos, Switzerland) is an ISO-Secondary Standard pyranometer that allows for accurate measurement of GHI (Global Horizontal Irradiance).

The three CMP 11 pyranometers were installed at the identical tilt angle as that of the PV modules. One pyranometer had a sensitivity 8.33 microvolt/W/m2, and the two other pyranometers had sensitivities of 9.16 microvolt /W/m2. For comparison’s sake, at the request of the plant owner, two pyranometers were connected to a data logger, and one pyranometer was connected directly to the plant PLC acquisition system.

Fig.1

Fig.1

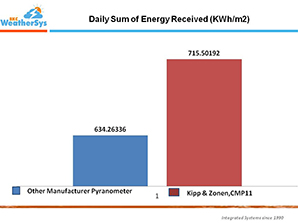

Our analysis showed that the percentage errors in measuring incoming solar radiation between all three pyranometers was less than 1.5%. However, the difference in the hourly solar radiation measured by the existing solar radiation measurement equipment and the three CMP 11 pyranometers was at least 11% (See Figures 1&2), with Kipp & Zonen pyranometers showing a higher irradiance than the older, existing pyranometer.

While a 11% difference in energy output in a given hour may not seem much at first glance, for a 5MW plant, this translates into a significant difference in plant output over a 24 hour cycle (Figure 2). As PV systems produce power in proportion to the intensity of sunlight striking the solar array surface, the difference in the actual output of a solar power system could be substantial.

Fig. 2

Fig. 2

Because the existing solar radiation measurement equipment was under reporting the incoming solar radiation, the performance of the plant as calculated on the basis of incoming solar radiation seemed better than it actually was. Once more accurate ground measurements were obtained, the plant owner could check module performance and plant efficiency with more confidence. The increased accuracy in solar radiation measurements also allowed the plant owner to make decisions on periodic maintenance and cleaning of PV modules.

Essential information for yield and performance ratio assessment

In summary, high precision irradiation measurements in PV power plants form an essential information base for yield and performance ratio assessment. Once up and running, the plant’s performance and yield are continuously monitored, analysed, and compared with the expected values.

The use of low quality radiation measurement instruments for reference purposes and for providing data for informing key decisions like scheduling maintenance and cleaning of panels, monitoring performance, and even predicting plant output is full with errors.

Even though the majority of projects are designed and commissioned on the basis of indirect estimates of solar radiation from solar databases, even after the plant is commissioned, it is critical to obtain accurate ground measurements to reduce uncertainties in energy production. In addition, ground measurements must be quality controlled by an expert to ensure that there are no errors in the data. Only high-precision measurement data collected on-site can provide meaningful and realistic conclusions about the performance of a PV power plant.”

BKC Weathersys Pvt. Ltd. is the leading provider of Solar Resource Assessment and meteorological technologies in India. They offer integrated solutions for solar radiation measurement and forecasting and are the distributor of Kipp & Zonen for India. Dr. Jaya Singh, the author of this article, is a Director of BKC WeatherSys.

BKC Weathersys Pvt. Ltd. is the leading provider of Solar Resource Assessment and meteorological technologies in India. They offer integrated solutions for solar radiation measurement and forecasting and are the distributor of Kipp & Zonen for India. Dr. Jaya Singh, the author of this article, is a Director of BKC WeatherSys.

For more information please visit http://weathersysbkc.com/.