There is an even easier way to do this by using a PET bottle. After six hours of sun light the water is safe to drink concerning micro-organisms. That is the rule of thumb, but it can be much faster. The PET bottle has to be clear and unscratched. This method is called SODIS (Solar Water Disinfection, www.sodis.ch) and uses the UV light from the sun to de-activate the E.coli bacteria. The required temperature for this process is only 40°C to 50°C.

By using solar ovens or solar cookers you can improve the heating power by concentrating the energy from the sun onto the object. To be able to evaluate the efficiency of different solar ovens Engineers Without Borders (EWB) in Sweden has constructed an evaluation unit. This unit registers the solar irradiation, water temperature and air temperature. The wind velocity is ‘watched’ as, for this test; the absolute value of wind velocity is not required as long as it is noticeably low.

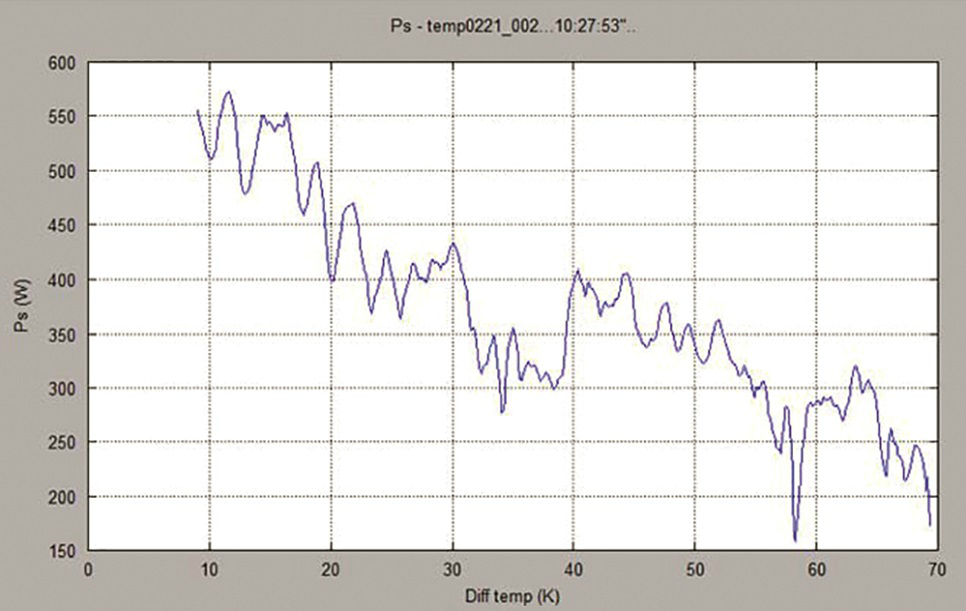

The setup closely follows the standardized test procedure presented by ASABE (American Society for Agricultural and Biological Engineering) in ASAE S580. This method calculates the normalized power as a function of the difference in temperature between water and air. The normalized power is calculated by dividing the instant power with the solar irradiation and multiplying by 700W/m2, which is used as a reference irradiation value.

Example showing absorbed normalized power (Ps) vs difference temperature (Difftemp) in a parabolic dish solar cooker.

Example showing absorbed normalized power (Ps) vs difference temperature (Difftemp) in a parabolic dish solar cooker.

The equipment uses an Arduino microprocessor, digital temperature sensors and a CM 5 First Class pyranometer from Kipp & Zonen, together with their AMPBOX. The CM 5 was bought by the Energy Technology Department at KTH Stockholm more than 35 years ago. The pyranometer was a gift to Engineers without Borders for this project. Kipp & Zonen calibrated the unit and now it’s working perfectly again, despite its age.

Staff member Collins, showing the measurement setup in Tatum. The CM5 pyranometer, a digital air thermometer and a ping-pong ball functioning as a wind velocity indicator.

Staff member Collins, showing the measurement setup in Tatum. The CM5 pyranometer, a digital air thermometer and a ping-pong ball functioning as a wind velocity indicator.

Data is logged every 4 seconds on a SD memory card. The water temperature is recorded at different places in the pot, or in several bottles in the same oven, to get a good average value. The air temperature is also logged as the main interest is the difference in temperature between the water and the air. The unit also comprises a Real Time Clock. Due to a very unreliable power network, solar panels and a 12 V battery are used to provide the necessary power to the equipment. Finally, water samples are taken for E.Coli analysis.

The photo shows a setup from Tatum in the North West Region of Cameroon where EWB started a small scale centre, DevICe (Development and Information Centre). The centre is run by a small team, mainly voluntary workers from the village with different backgrounds, using materials provided by EWB. The partner in Cameroon is Leéiyen Systems, a NGO that works in the area with children and health related projects. We started the tests in Sweden during the summer of 2014 but, as the summer in Sweden is too short to complete the tests, the work was continued in a sunnier place.

Recording the solar irradiation will take place every day, even if no tests will be performed. This provides a more accurate picture of the potential of solar radiation for water disinfection in a particular location than can be given by other available information sources. Engineers Without Borders looks forward to large scale applications of this simple method for water disinfection, as a result of this project.

Article by Stefan Karnebäck of Ingenjörer utan Gränser (Engineers without Borders) in Sweden -

Engineers Without Borders is a customer of Toragon AB of Umeå, the Kipp & Zonen distributor for Sweden.

Bibliography:

1 ‘The Microbiology of Solar Water Pasteurization, with Applications in East Africa’, Robert Metcalf, California State University, Sacramento, California.

The Development and Information Centre in Tatum, Cameroon

The Development and Information Centre in Tatum, Cameroon